|

| Canon P + Canon 50mm f1.8 Foma 100 in Rodinal 1+50 |

After many decades of collecting and using classic audio equipment and film cameras, I've learned to accept that sometimes I win, sometimes I lose, but most of the time I break even. And the only reason there is that possibility of breaking even is because I learned to DIY.

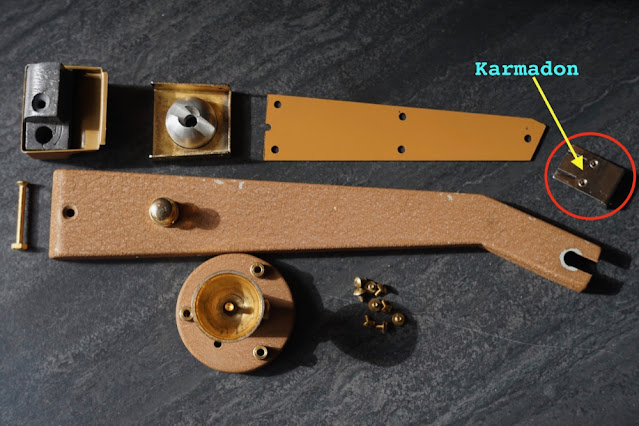

This tonearm came with a KS Musicmaster Model 25B12GST idler-driven turntable, which I thought I could resuscitate. Alas, the turntable was beyond saving because a lot of important parts were missing. The tonearm had no head shell slide and the cartridge pin contact points + wiring harness were gone. For many years this tonearm was boxed up along with other parts units sitting in storage.

One day I had an epiphany - will the Karmadon head shell slide fit?

I'm happy to report that the two types of head shell slides that my buddy, Sergiy, manufactures for his Gray Research tonearm clone work on this Japanese clone as well as on my original Gray Research 108C. Above left is a solid shell and on the right is a shell with a hole to accommodate the triple play feature of the General Electric RPX and VRII mono cartridges.

Despite the carnage brought upon the Ukrainians by a deranged autocrat, my Karmadon head shells arrived in less than two weeks. We really have to admire and support these people!

I rewired the tonearm and blu-tacked 4 pennies to make up for the lost hardware.

Since the Karmadon head shell slide is lighter than the original, I used all three copper weights Sergiy provided, added 2 x 5 centavo coins + the GE VRII cartridge = 25 grams.

Voila!👍

|

| For more viscous damped tonearm set up information, please click here! |

Even with my 20+ years of experience using this tonearm, it took me a while to dial-in the proper weight compensation due to the missing hardware + adapted head shell slide. Getting a viscous damped tonearm to function properly isn't for the faint of heart and requires patience. If you don't possess these virtues, I suggest you don't consider using one. But I must say the results are well worth it!😊

|

| Musicmaster Model 12 + GE VRII |

Let's listen to a few monaural hifi tunes!

🎶🎻🎹🎷