This is the final installment of my Japanese idler turntable adventure but as Sean Connery said, "Never say never again..." 😉

Showing posts with label Japanese Idler. Show all posts

Showing posts with label Japanese Idler. Show all posts

Sunday, September 14, 2025

Thursday, August 22, 2024

Japanese Idler-Driven Turntable Part 7: Kenwood PC350

Kenwood PC350 - a Japanese TD124 spinning a jazz tune!😉

Friday, March 22, 2024

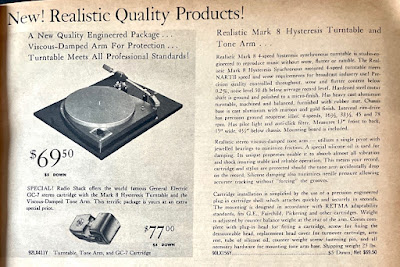

Japanese Idler-Driven Turntable Part 6: Realistic Mark 8

Just like cars, a new turntable model has to be introduced every year or two to keep consumers' interest and convince them that newer is better.😊

|

| from page 37 of the 1960 Radio Shack Catalog |

The Realistic Mark 8 improved upon the similar looking "motor unit-stye" Mark 7 in Part 4 of this series by adding a 16 rpm speed and supplying a half pound heavier cast aluminum platter.

Saturday, September 2, 2023

Japanese Idler-Driven Turntable Part 5: Lafayette PK300

I bought this Lafayette PK300 idler-driven turntable because it looked like an improved Shield MO-19 (aka NEAT P58H) with the added feature of an eddy current pitch control as found in the Garrard 301/401 and Thorens TD124.

Friday, July 7, 2023

Japanese Idler-Driven Turntable Part 4: Realistic Mark-7

Here's a tale of two idler-driven turntables of Japanese origin sold by Radio Shack in the late 50s. They share the same model badge and engineering features but they aren't exactly twins.🤔

Saturday, May 6, 2023

Saturday, March 4, 2023

Japanese Idler-Driven Turntable Part 2: NEAT P58H/Shield MO-19

In the early 2000s, the swinging tonearm mount of the Shield MO-19 caught my attention because it looked like the perfect partner for my Velvet Touch viscous damped tonearm. It turned out that this Japanese 4-speed idler-driven turntable is actually a rebadged NEAT P58H.

Saturday, September 3, 2022

Japanese Idler-Driven Turntable Part 1: Pioneer PL6U

Ever since I discovered the Shield MO19 (aka Neat P58H) and Realistic MkVII at the turn of the new millennium, I've become fascinated by, and in the process have collected a few Japanese idler-driven turntables. To my ears, none of them measure up to the Garrard 301, 401 or Thorens TD124. However, the models I'll be covering in this series, IMHO, offer great musical value for money when properly sorted.

For this initial installment, I'm featuring the Pioneer PL6U, which I used as an interim turntable when I returned to the US in 2016. It's the little brother of the Pioneer PL7, which was built to much higher specifications.

Subscribe to:

Comments (Atom)